Fordonsindustri

Induktionsvärme används inom en mängd olika områden i fordonsindustrin. ENRX är en pålitlig leverantör som samarbetar med biltillverkare, underleverantörer på första nivå och underentreprenörer över hela världen.

Introduktion

Övergången mot Industri 4.0 inom fordonsindustrin, med integrerade försörjningskedjor, talar för induktionsvärme eftersom processen är lätt att kontrollera och övervaka. Induktionsvärme kan användas för värmebehandling av i princip alla karossdelar, chassin, drivlinor, elektriska eller motorrelaterade delar i ett fordon. Även om ENRX har varit en del av fordonsindustrin i årtionden, hittar vi ständigt nya sätt att förbättra värmeeffektivitet, processer och resultat.

- Induktionsvärme för fordonsdelar av metall

- Induktionsvärme för många komponenter i elfordon

- Induktionsvärme för att förverkliga visioner om smarta fabriker

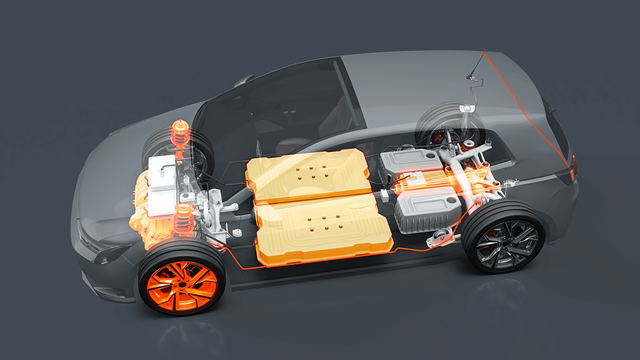

Induktionsvärme används inom en mängd olika områden vid produktion av elbilar.

Se hur induktionsvärme är idealisk för att förädla komponenter som används i alla moderna elbilar.

Bildgalleri

-

ENRX is the world’s largest induction hardening equipment maker with more than 70 years’ experience.

-

Customised coil for induction hardening of camshafts.

-

ENRX induction camshaft hardening solutions are used by many of the leading names in the truck, bus, excavator and earth-moving equipment industries. Our systems are also widely used to harden marine camshafts.

-

High troughput and consistent heating outcomes are essential when heat treating bars and shaft

-

ENRX design, make and maintain customised coils for camshaft hardening. These formed coils deliver precise heat patterns and penetration depts for perfect hardening results.

-

An ENRX robot-type crankshaft hardening system in action. All our systems feature mechanical and control innovations that minimize Total Indicated Run-Out

-

Car crankshafts, truck crankshafts, marine crankshafts - ENRX systems are used worldwide to harden every imaginable type of crankshaft in a wide range of production volumes.

-

Seamless induction hardening of large rings and gears.

-

Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel.

-

Induction hardening increases the hardness and durability of steel

-

A programmable quenching cycle in work

-

A HardLine Centerless Pusher machine heat treats steel bars

-

Induction hardening of steering rack

-

Double hardening for double productivity. The quenching phase inside a single cabinet hardening machine with twin tailstocks and centres.

-

Induction brazing of aluminium parts

-

ENRX has unrivalled expertise in making efficient solutions for aluminium brazing.

-

Induction is a high troughput, no-contact heating method. It helps ensure strong yet barely visible joints-and the oustanding aesthetics expected by today's customers.

-

High-quality banjo nipples being brazed under a controlled atmosphere in a customised ENRX brazing machine.

-

Induction brazing of brake linings

-

Induction heating is a perfect method for high troughput brazing of evaporator and condenser connections

-

Induction brazing of a heat exchanger.

-

Induction is the preferred bonding method in the automotive industry.

-

Induction is the main method for curing adhesives and sealants for car components such as doors, hoods, fenders, rearview mirrors and magnets.

-

Induction bonding is the primary method for aluminium and steel panel heating

-

Induction bonding. Universal fixture for lab/process trials

-

Full-ring bonding with two-turn flexible coil

-

Aluminium hood spot bonding tool. Note: The absence of clamps, minimal nest and realtively small curing areas.

-

Hardening and tempering of ball studs and housing

-

Hardening and tempering of brake callipers

-

Hardening and tempering of piston rods

-

Hardening and tempering of constant velocity joints

-

Hardening and tempering of transmission parts. Shrink fitting of transmission bearings

-

Hardening and tempering of wheel bearings, hubs and spindels

-

Hardening and tempering of steering components

-

Hardening, tempering and welding of drive shafts

-

Hardening, tempering and shrink fitting of rotor shaft and motor housing

-

Hardening, tempering and shrink fitting of rotor shaft. Shrinking of motor housing. Drying of resin coating on rotor and stator.

-

Tempering solutions from ENRX are present in the automotive and automotive-supply industries.

Kontakta oss

Letar du efter support eller köpinformation, kontakta oss här.