Induction brazing

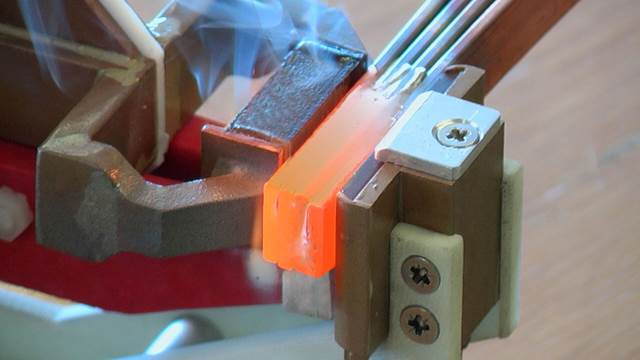

Induction brazing is the perfect choice for brazing of bars, strands, rings and wires in motors, generators and transformers.

ENRX rental equipment is ideal for brazing jobs for the following components:

- Generators

- Transformers

- Turbo generators

- Switch gears

- Motors

Induction brazing is the perfect choice for such parts.

First, the heat is localized. This means that precise Heat Affected Zones can be defined in advance.Second, high density, no-contact heat in precisely demarcated zones means:

- Minimal heat spread

- Minimal risk to insulation materials

- Minimal risk of deformation

When mobility is needed coils can be attached to compact handheld power outputs. As easy to operate as a regular power tool, these handheld units feature long and flexible power cables and are easily attached to commonly available balancers or positioners for extra comfort and productivity.

Why choose induction over flame brazing?

1. Speedier solution

Induction heating transfers more energy per square millimetre than an open flame. Induction can therefore braze more parts per hour than alternative processes. Rapid and precise heating results in less mass to be heated. And there is less damage to surrounding insulation.

2. Consistent performance

Induction heating is controllable and repeatable. Enter the desired process parameters and the induction equipment will repeat the heating cycles.

3. Unique controllability

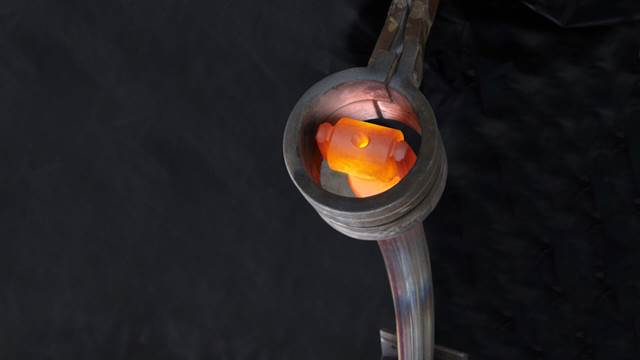

Induction lets operators view the brazing process, something that is difficult with flames. This and precise heating minimize the risk of overheating.

4. More productive environment

Open flames create uncomfortable working environments. Induction is quiet and clean. It is easy to extract fumes and there is virtually no increase in ambient temperature..

5. No-contact process

Induction produces heat within the base metals—and nowhere else. Unlike flame heating the base metal never comes into contact with the heat source. The homogeneous and controlled heat minimizes distortion, and there is no danger to create hydrogen embrittlement.