Induction hardening

Our hardening solutions are used by many of the world’s leading car manufacturers and their suppliers.

What is induction hardening?

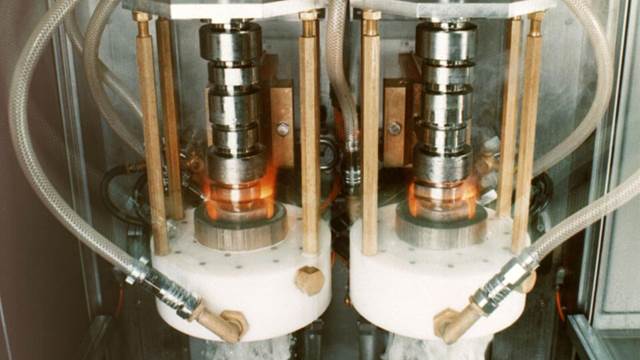

Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Induction is a no-contact process that quickly produces intense, localized and controllable heat. With induction, only the part to be hardened is heated. Optimizing process parameters, such as heating cycles, frequencies and coil and quench design, result in the best possible outcomes.

What are the benefits?

- A fast and repeatable process that integrates easily into production lines

- Clean, safe, energy-efficient, and typically with a small footprint

- Individually treated workpieces; each piece is hardened to its precise specification

Where is it used?

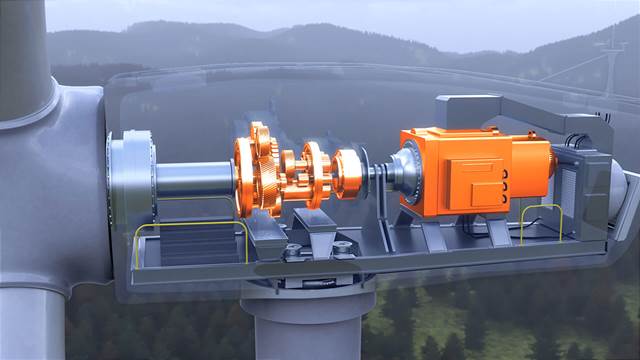

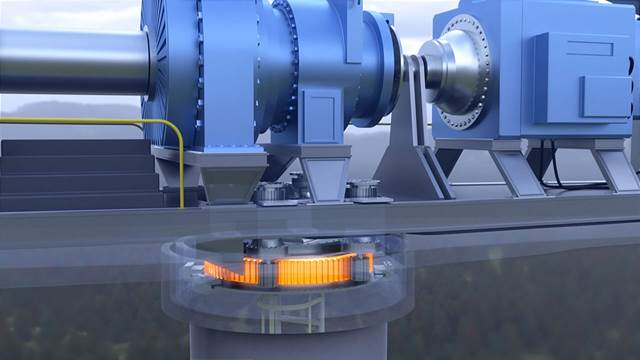

Induction is used to harden numerous components. Here are just a few of them: gears, crankshafts, camshafts, drive shafts, output shafts, torsion bars, rocker arms, CV joints, tulips, valves, rock drills, and slewing rings, as well as inner and outer races.

ENRX hardening solutions are utilized across a wide range of industries globally. However, most systems fall into the following categories.

related industries

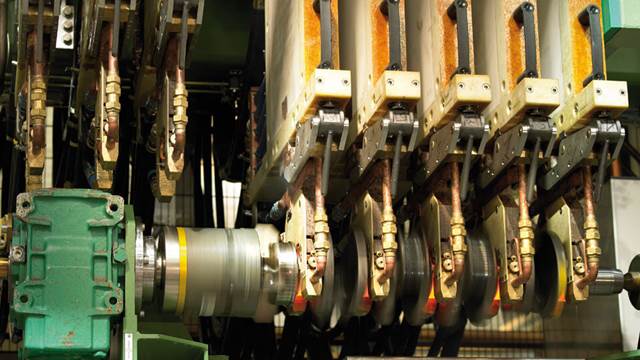

What equipment is available?

HardLine is the ENRX family of hardening systems that offers vertical, horizontal, rotary table and centerless equipment. At the heart of our hardening solutions are Sinac generators, available with output power ratings and frequencies ranging from 5–2000 kW and 0.3–350 kHz. ENRX can also deliver turn-key hardening plants that include handling equipment, washing/straightening processes and process development as well as service and support programs.